|

|

|

ProductETechnical Information

Automatic Feeding System dg`b-130`i

Automatic Feeding System dg`b-130`i

|

| Automatic Feeding System |

dg`b-130`i |

|

|

| ¡ Automatic Feeding System for core drill. Professional technique is installed

in CPU. |

|

| ¡ Easy to attach CONSEC drill carriage. |

| ¡ Integrated reinforced steel sensor function.It enables not to cut reinforcing

steel in case of small diameter drilling targeting earthquake strengthening.After

detecting reinforcing steel, core drill automatically stops using built-in

gReinforcing steel detection softwareh |

| ¡ 16 steps of drill load settingLoad setting is possible up to 16A depend on core drill and working situation. |

| ¡ Automatic stop function After complete drilling, feeding and drilling

automatically stop. |

| ¡ 2 feeding speeds make it possible to drill small diameter to big diameter. |

| ¡ Reverse function.After completing drilling, push the Auto Feed button,

drill motor comes up for maximum 5 minutes. |

| ¡ CE Marking and RoHS regulation are certified. |

| Specifications |

| Power Supply |

Single-phase 230V ` 50Hz |

| Max. Power Consumption |

75W |

| Maximum rotating speed of output shaft |

2.99(Hi)/1.60(Lo)min-1 |

| Max. Feeding Speed |

CL-49 series |

approx. 105(Lo)/197(Hi)mm/min |

| CL-59 series |

approx. 70(Lo)/131(Hi)mm/min |

| CL-74 series |

approx. 83(Lo)/155(Hi)mm/min |

| Applicable Core Drills |

Max. Rated Current |

Less or equal 16A |

| Type |

SPF Core Drill, E type

SPN Core Drill, E type

SPZ Core Drill, E type

SPM Core Drill, E type

SPO Core Drill, E type

SPX Core Drill, E type |

| Reinforced Sensor |

CC mode |

Normal drilling |

| FC mode |

Drilling automatically stop after reinforcing steel detected. Applicable

core bit dia. from 25 to 77mm (3h) |

| Size |

247~189~279mm |

| Weight iIncluding cordj |

7.1kg |

|

|

¦ Drill motor: SPX-24A

¦ Drill carriage: CL-743E

¦ Pole Base: SB-741-1050

¦ Core Bit: A rod screw three separate type core bit

¦ Automatic feeding system: EHAC-130A |

| Reinforcing steel sensor function |

¡ Principle of reinforcing steel sensor function

It needs a practice to detect the reinforcing steel in a concrete by hand feeling.

In case of drilling through hole from 1m to 2m, the reinforcing steel at core drill side can be detected by Reinforcing Steel Scanning Machine. So we donft need to care about cutting of the reinforcing steel. However there is a possibility to cut reinforcing steel which is not detected reinforcing steel by Reinforcing Steel Scanning Machine and backside of material.

So we developed gReinforcing Steel Detection Softwareh to prevent from cutting reinforcing steel by mistake.

gReinforcing Steel Detection Softwareh is always monitoring drilling speed of core bit in order to judge whether the reinforcing steel exist or not in a concrete. If the reinforcing steel is grinded during drilling, the software makes Core Drill stop instantly. So reinforcing steel isnft cut.

|

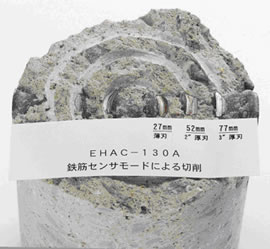

The damage for reinforcing steel (Dia. 25mm) by using EHAC-130Aiwith reinforced

sensorj |

|

|

| Skilled worker drilling by hand feeding |

Drilling using gReinforced Sensor Modeh |

| Option parts |

|

|

| Parts name |

EHAC Stopper for 49 |

EHAC Stopper for 55,59 |

| Weight |

0.2kg |

0.2kg |

| Picture |

|

| Parts name |

dg`b Right Handle |

| Weight |

1.2kg |

| Picture |

|

|

|

|

|

@ |