|

|

|

ProductETechnical Information

Automatic Feeding System dg`b-WO`w

Automatic Feeding System dg`b-WO`w

|

| Automatic Feeding System |

dg`b-WO`w |

|

|

| ¡ Automatic Feeding System for Core Drill.Artistic performance is installed in CPU circuit |

|

| ¡ Simple and compact Automatic Feeding System only installed high frequency

of usage function. |

| ¡ Installed reinforced steel sensor function.It enables not to cut reinforcing

steel in case of small diameter drilling targeting earthquake strengthening.When

the reinforcing steel detected, Core Drill automatically stop using built-in

gReinforcing steel detection softwareh |

| ¡ 13 Steps of drill load settingLoad setting is possible up to 21A depend on Core Drill and working situation. |

| ¡ Setting value of automatic stop function after complete drilling is adjustable.

|

| Specifications |

| Power Supply |

Single-phase 110-120V ` 50/60Hz |

| Max. Power Consumption |

52.8W |

| Maximum rotating speed of output shaft |

2.0min-1 |

| Max. Feeding Speed |

CL-49 series |

About 105mm/min |

| CL-59 series |

About 77mm/min |

| Applicable Core Drills |

Max. Rated Current |

Less or equal 21A |

| Type |

SPF Core Drill, E type

SPN Core Drill, E type

SPZ Core Drill, E type

SPM Core Drill, E type

SPO Core Drill, E type |

| Reinforced Sensor |

bb mode |

Nomal drilling |

| eb mode |

Drilling automatically stop after reinforcing steel detected. Applicable Core Bit dia. From 25 to 77mm (3h) |

| Size |

195~166~275mm |

| Weight iIncluding cordj |

6.1kg |

|

| Automatic Feeding system F EHAC-80A |

|

| ¡ Description of control panel |

|

1 Set the drill mode |

|

|

When the power supply cord is plug to the power supply, digital display indicates current drill mode gCCh or gFCh.

If the drill mode needs to be changed, push the gClutch buttonh and gAuto Stop buttonh more than 2 seconds at one time, then you releace your hands when the display changed. |

|

|

2 Start initial drilling around 5mm by manual. |

|

|

Hold down gDrill buttonh more than 0.2 seconds to start drilling.

Hold the feeding handle and push the gClutch buttonh to release the clutch, then start cutting by feeding handle. |

|

|

3 Change manual cutting to automatic cutting. |

|

|

To start automatic cutting, push the gClutch buttonh, after that push the

gFeed buttonh. |

|

|

4 Set the motor load of Core Drill. |

|

|

Change the display current value pushing the gDrilling Load Setting buttonh

The current value has to be adjusted depend on Core Drill load condition. For example, sound of motor, rotation speed, feeding speed, etc. |

|

|

5 Set automatic stop function.iIf you needj |

|

|

If automatic stop function work, drilling will automatically stop after penetrating

Automatic stop function can be set and cancel by pushing gAutomatic Stop buttonh. |

|

|

6 If you would like to stop drilling on the way, push the gDrill buttonh |

|

7 Hold the feeding handle and push the gClutch buttonh, clutch will be

released. You need to move the Drill Head by feeding handle and taking

out drilled core. You can finish the drilling. |

| Reinforcing steel sensor function |

¡ Principle of reinforcing steel sensor function

It needs a practice to detect the reinforcing steel in a concrete by hand feeling.

In case of drilling through hole from Pm to Qm, the reinforcing steel at core drill side can be detected by Reinforcing Steel Scaning Machine. So we donft need to care about cutting of the reinforcing steel. However there is a possibility to cut reinforcing steel which is not detected reinforcing steel by Reinforcing Steel Scaning Machine and backside of material.

So we developed gReinforcing Steel Detection Softwareh to prevent from cutting reinforcing steel by mistake.

gReinforcing Steel Detection Softwareh is always monitoring drilling speed of core bit in order to judge whether the reinforcing steel exist or not in a concreat. If the reinforcing steel is grinded during drilling, the software makes Core Drill stop instantly. So reinforcing steel isnft cut.

|

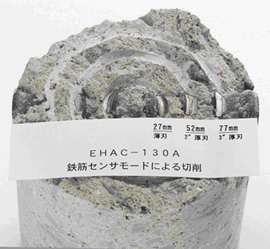

The damage for reinforcing steel (Dia. 25mm) by using EHAC-130Aiwith reinforced

sensorj |

|

|

| Skilled worker drilling by hand feeding |

Drilling using gReinforced Sensor Modeh |

| ¡ Instructions and directions for use of gReinforced Sensor Functionh. |

|

1 |

Do not use except drilling for earthquake strengthening.

gReinforced Sensor Modeh has a possibility to cut electric ductwork, telephone line ductwork, water pipe, gas pipe, regin ductwork, steel wire and, etc. |

|

2 |

Use Core Bit diameater more than 25mm less than 77mm(3h)

If improper Core Bit is used, there is a possibility that Core Drill doesnft stop after Core Bit contact to reinforcing steel. |

|

3 |

Do not use worn Core Bit

The cutting edge of Core Bit is like a sensor of gReinforcing Steel Detection Softwareh. If worn Core Bit is used, detection performance will be low. There is a possibility that Core Drill doesnft stop after Core Bit contact to reinforcing steel. |

|

4 |

Even if Automatic Feeding System is used, there is a possibility to cut

reinforcing steel depending on a Core Drill condition and working site

situation. So during Drilling, do not get away from Core Drill and check

the sound of drilling and change of water color. |

| Option parts |

|

|

| Parts name |

dg`b Stopper for 49 |

dg`b Stopper for 55,59 |

| Weight |

0.2kg |

0.2kg |

| Picture |

|

| Parts name |

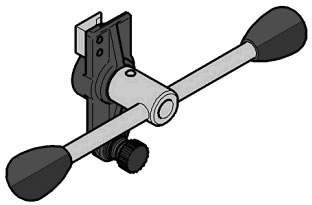

dg`b Right Handle |

| Weight |

1.2kg |

| Picture |

|

|

|

|

|

@ |